News

Send-off

November 2024

Dear Followers,

everything passes - it is known that every project has its beginning and its end. Our ErgoDesign journey is slowly coming to an end. Yet our actions remain. We recommend the course we developed and the additional materials mentioned on our social media. We would like to thank all partners and you - our observers. It was a pleasure to work for you over the past months and we promise that we will be back - that is why we do not say "goodbye" but "see you soon"- in the near or distant future!!

Your ErgoDesign Team

Last meeting

of the ErgoDesign project partners

November 2024

On 18.11.2024, the last meeting of the ErgoDesign project partners took place. This time, we were hosted by the walls of the Poznań University of Technology - the project leader, and the meeting was as real as possible (and not online as at the beginning of our cooperation). The meeting was started by prof. Beata Mrugalska, and then, step by step, we discussed all the elements necessary to summarize our several years of activities. After a day full of discussions and impressions, the leader surprised everyone by sweetening our last moments together

Anna Stasiuk-Piekarska, PUT

On a virtual tour

November 2024

Today we are taking you on a virtual tour: The largest and most sophisticated Dental Treatment Center in the world. Cooperation with various partners from the world of medicine has enriched our experience, but most of all the course that we have given into your hands!

https://www.youtube.com/watch?v=kZ6HRcxjwLg

Tihomir Dovramadjiev, TUV

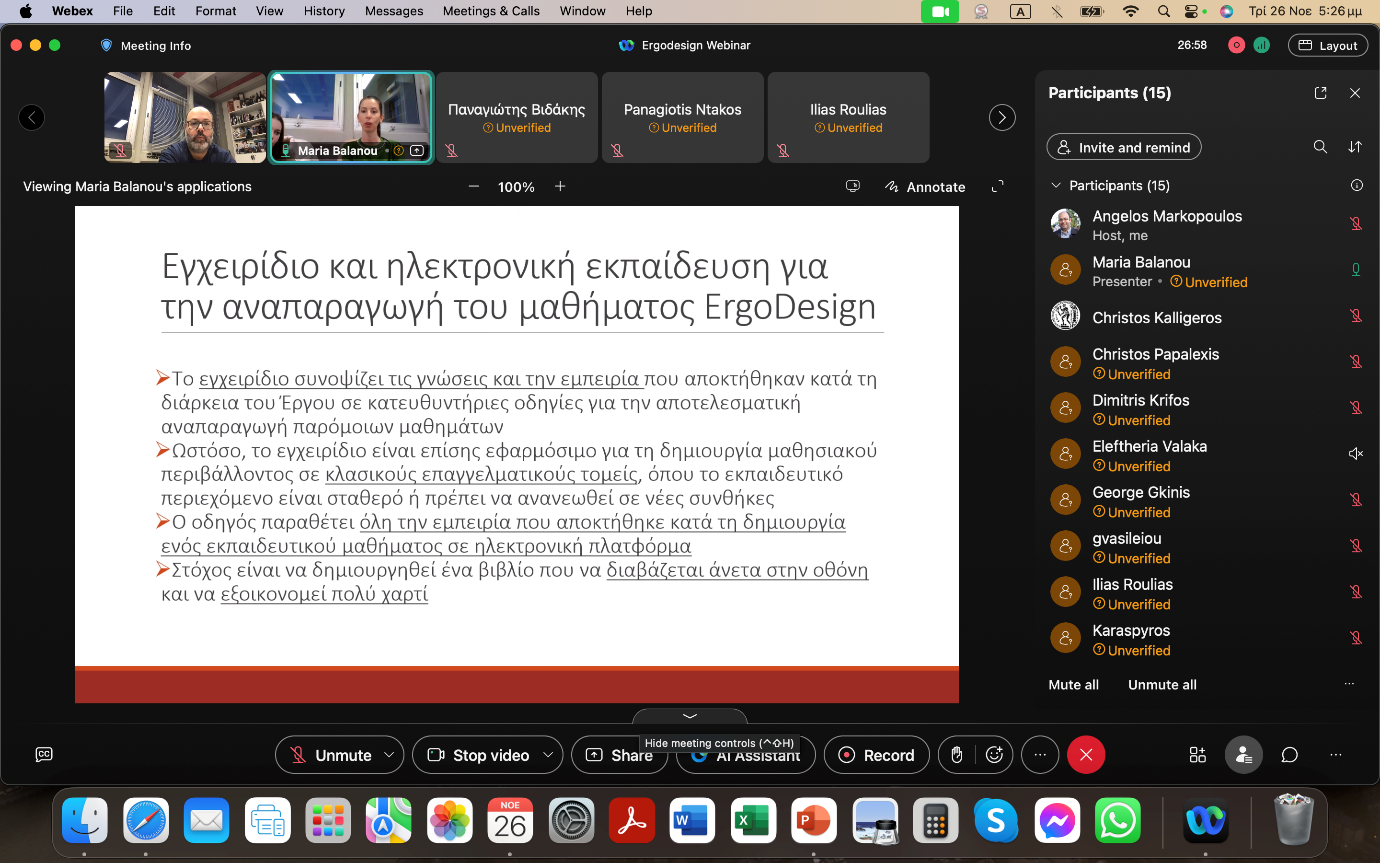

Webinars-NTUA

November 2024

NTUA successfully hosted two webinars for the ERASMUS+ 2021-1-PL01-KA220-HED-000031182 "ErgoDesign – Improving Digital Skills for Ergonomics and Bioengineering Innovations for Inclusive Health Care" on November 26th and November 28th, 2024, in both Greek and English versions. These webinars provided an opportunity for participants to explore the project’s objectives and outcomes. The sessions featured thorough presentations of all Intellectual Outputs, and feedback from attendees was positive.

Participants particularly appreciated the Dynamic Toolkit, finding it helpful, user-friendly, and beneficial. The ErgoDesign course also received a strong impression, with attendees describing it as well-structured, detailed, and an effective educational tool. Furthermore, the collaboration platform was evaluated as robust, organized, and easy to navigate, significantly enhancing the overall user experience. The handbook was also seen as a valuable resource, inspiring participants to pursue further research and engage in similar projects in the future.

Chrysi Giakoumidi, NTUA

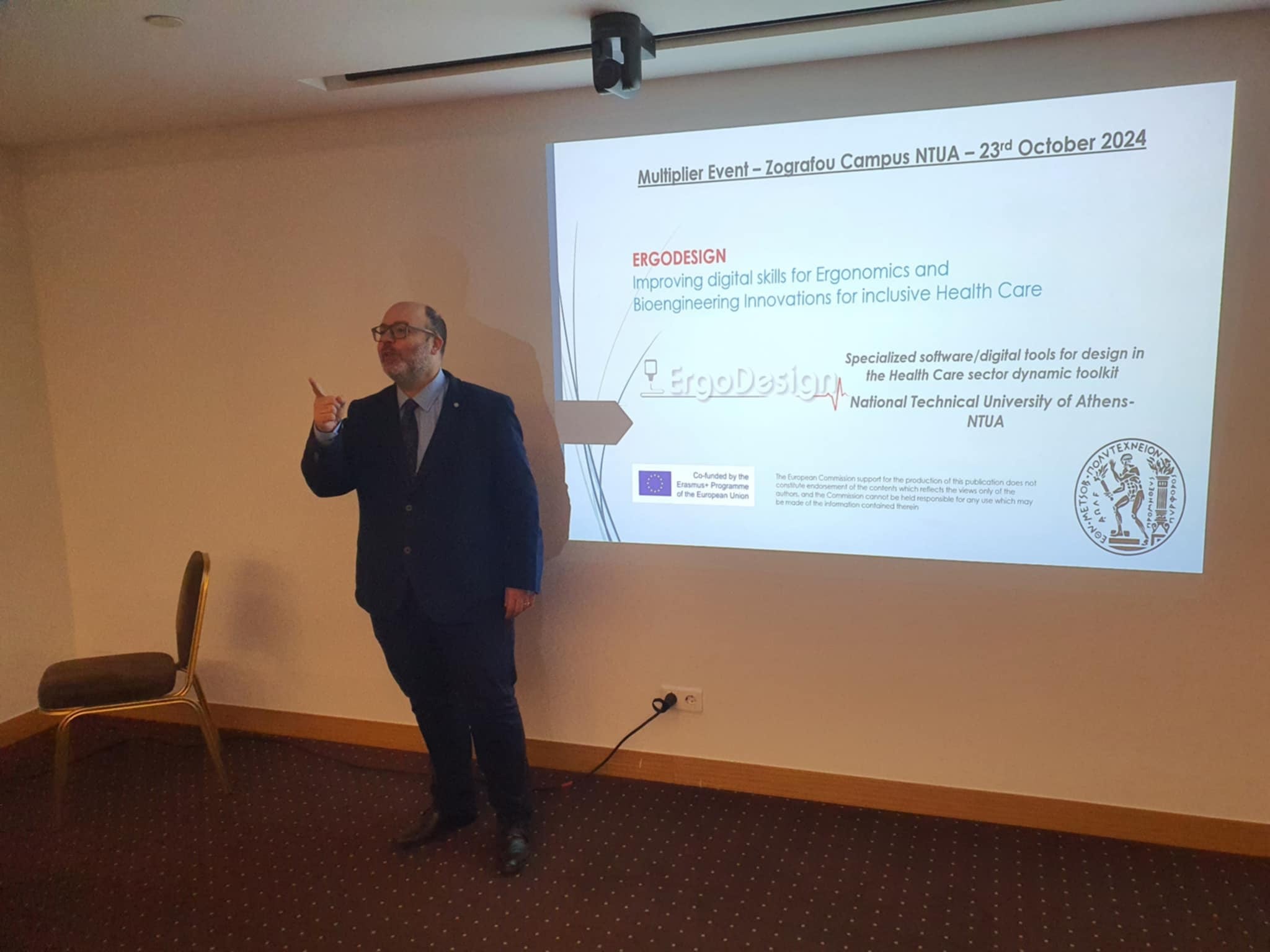

Multiplier event-NTUA

October 2024

The multiplier event of the ERASMUS+ 2021-1-PL01-KA220-HED-000031182 "ErgoDesign – Improving digital skills for Ergonomics and Bioengineering Innovations for inclusive Health Care" was successfully organized by NTUA in Athens on October 23th, 2024. Many participants had the opportunity to learn about the aims and results of the project. The conference included comprehensive presentations of all Intellectual Outputs, and feedback from attendees was very positive.

Many participants found the Dynamic Toolkit to be very helpful, beneficial and user-friendly. The ErgoDesign course also made a strong impression, with the attendees describing it as well-written, detailed and an effective educational resource. Additionally, participants evaluated the collaboration platform as robust, well-structured, and easy to use, significantly enhancing the user experience. Finally, the handbook was regarded as a valuable resource, motivating participants to pursue further research and work on similar projects in the future.

Chrysi Giakoumidi, NTUA

A short presentation of one of the scientific articles

October 2024

We would also like to present a summary of one of the articles that was created as a result of the ErgoDesign project (authors: Diana Pavlova, Tihomir Dovramadjiev, Ivan Peev, Dimo Daskalov, Nikolay Mirchev, Rozalina Dimova, Julia Radeva, Gyula Szabo, Beata Mrugalska & Andromachos Kandioglou). "The human factors that are directly present in dentistry are taken into account. This gives reason to pay serious attention to the application of surgical guides in practice in order to support human activity. Surgical guides play a critical role in ensuring accurate implant positioning, supported by comprehensive examinations using dental impressions and CT scans. Using specialized software, digitally personalized surgical guides are designed to take into account the optimal implant position, angle and depth. These guides, created using CAD/CAM techniques, act as precise templates during surgery, guiding the dentist to place the implants precisely according to the pre-planned design. The surgical procedure involves careful site preparation and implant placement, followed by post-operative care to ensure successful healing and integration. By incorporating technological advances such as CT scanning, digital planning and 3D printing, the use of surgical guides exemplifies the potential of Industry 4.0 to improve the accuracy, efficiency and outcomes of dental implant surgery." More information: https://baehfofficial.wixsite.com/.../erasmus-project...

Tihomir Dovramadjiev, TUV

Multiplier event - PUT

October 2024

On October 24, the ErgoDesign project conference (implemented as part of the Erasmus+ project, 2021-1-PL01-KA220-HED-000031182) was held. Within the walls of the project leader - Poznań University of Technology - consortium partners from various European universities (Poznan University of Technology, Technical University of Varna, Óbuda University, National Technical University of Athens and Technická Univerzita v Košiciach) presented their activities in the project's subject matter. Our international event was opened by the project manager "ErgoDesign Improving digital skills for Ergonomics and Bioengineering Innovations for inclusive Health Care" - prof. Beata Mrugalska. In addition, participants could take part in a training conducted by Ensafe in the field of inclusive healthcare. We consider the event to be very successful and we invite you to continue following our activities (ergodesigner.eu; https://www.linkedin.com/.../ergodesign-erasmus-plus.../). We are currently implementing webinars and publications that are the result of our activities, and a partners' meeting summarizing the entire project is approaching.

Anna Stasiuk-Piekarska, PUT

Scientific publications straight from ErgoDesign Partner

October 2024

The ErgoDesign project is not only about didactic courses, but also about scientific development. All partners have repeatedly mentioned topics related to the ErgoDesign project in their scientific articles and conference presentations. Today we will only indicate information on where you can find the mentioned publications. And soon we will tell you more about them.

Here they are:

https://link.springer.com/chapter/10.1007/978-3-031-71079-7_17

Tihomir Dovramadjiev, Exploring the dynamics of implantology: insights into anatomy and practical examples, https://www.ieti.net/TES/2024V8I1/5.pdf?fbclid=IwY2xjawGAcDpleHRuA2FlbQIxMAABHSIZ2YLb5_HLjkNvp0iO5uEEsVbNCBemcmV7bH-FjMctGicPNfm9M6QRUg_aem_UcQcXoBCyOZdyN6Fr2rZZg

Diana Pavlova, Tihomir Dovramadjiev, Dimo Daskalov, Ivan Peev, Nikolay Mirchev, Rozalina Dimova & Julia Radeva (2024). Synergizing Artificial Intelligence and Human Factors in Hybrid Intelligence Dentistry for Automatic Prototyping. In: Senjyu, T., So–In, C., Joshi, A. (eds) Smart Trends in Computing and Communications. SmartCom 2024 2024. Lecture Notes in Networks and Systems, vol 947. Springer, Singapore. https://doi.org/10.1007/978-981-97-1326-4_35 https://link.springer.com/chapter/10.1007/978-981-97-1326-4_35

Diana Pavlova, Tihomir Dovramadjiev, Dimo Daskalov, Nikolay Mirchev, Ivan Peev, Julia Radeva, Rozalina Dimova, Kalina Kavaldzhieva, Beata Mrugalska, Gyula Szabo & Andromachos Kandioglou (2024). 3D Design of a Dental Crown with Artificial Intelligence Based in Cloud Space. In: Nagar, A.K., Jat, D.S., Mishra, D.K., Joshi, A. (eds) Intelligent Sustainable Systems. WorldS4 2023. Lecture Notes in Networks and Systems, vol 817. Springer, Singapore. https://doi.org/10.1007/978-981-99-7886-1_37 https://link.springer.com/chapter/10.1007/978-981-99-7886-1_37

Tihomir Dovramadjiev, Diana Pavlova, Rusko Filchev, Rozalina Dimova, Dimo Dimov, Kalina Kavaldzhieva & Beata Mrugalska (2023). Technological and Human Approach in Complete Restoration of the Dental Teeth Jaws with Biocompatible Materials. In: Senjyu, T., So–In, C., Joshi, A. (eds) Smart Trends in Computing and Communications. SMART 2023. Lecture Notes in Networks and Systems, vol 645. Springer, Singapore. https://doi.org/10.1007/978-981-99-0769-4_43 https://link.springer.com/chapter/10.1007/978-981-99-0769-4_43

Diana Pavlova and Tihomir Dovramadjiev. Visualizing health: the significance of medical imaging and human factors. IETI Transactions on Ergonomics and Safety (TES) 2024, Volume 8, Issue 1, 1-11, USA, ISSN 2520-5439, DOI:10.6722/TES.202404_8(1).0001. https://www.ieti.net/TES/2024V8I1/1.pdf

Diana Pavlova, Tihomir Dovramadjiev, Ivan Peev, Dimo Daskalov, Nikolay Mirchev, Rozalina Dimova, Julia Radeva, Gyula Szabo, Beata Mrugalska & Andromachos Kandioglou (2024). Human Factors and Use of the Surgical Guide in Dentistry—Real Practice Example. In: Kaiser, M.S., Xie, J., Rathore, V.S. (eds) Intelligent Strategies for ICT. ICTCS 2023. Lecture Notes in Networks and Systems, vol 941. Springer, Singapore. https://doi.org/10.1007/978-981-97-1260-1_22 https://link.springer.com/chapter/10.1007/978-981-97-1260-1_22

Diana Pavlova, Tihomir Dovramadjiev, Dimo Daskalov., Rozalina Dimova., Beata Mrugalska, (2024). File Formats and Digital Data Transfer for Dental Needs. In: Yang, XS., Sherratt, R.S., Dey, N., Joshi, A. (eds) Proceedings of Eighth International Congress on Information and Communication Technology. ICICT 2023. Lecture Notes in Networks and Systems, vol 696. Springer, Singapore. https://doi.org/10.1007/978-981-99-3236-8_38 https://link.springer.com/chapter/10.1007/978-981-99-3236-8_38

Tihomir Dovramadjiev, TUV

ErgoDesign News,

October 2024

We recommend you a report from the Hungarian event summarizing project activities at our partner. More:

https://bgk.uni-obuda.hu/beszamolo-az-ergodesign-projektzaro-rendezvenyrol/

Our international conference ErgoDesign,

October 2024

Beata Mrugalska, PUT

Important information

September 2024

On behalf of our Bulgarian Partner, we invite you to the channel with additional information supplementing our course:

Our partner about us

September 2024

We recommend an interview about the project and distance learning with one of our partners: Dr. Gyula Szabó from Obuda University:

https://edti.uni-obuda.hu/2024/09/mi-ujsag-a-k-mooc-ban-interju-dr-szabo-gyulaval

Important information - our conference

September 2024

Dear Followers,

We are pleased to inform you that our conference is being prepared - only for you! The event will take place at the Poznań University of Technology, and we can already reveal that we are preparing interesting workshops for you!

Anna Stasiuk-Piekarska, PUT

Our new partner - about Prospecto Srl

July 2024

Prospecto Srl is an innovative startup founded in 2019 by a team of professionals with decades of expertise in European project design, professional training, public procurement, and open tender procedures. The startup develops innovative solutions, both technologically and procedurally, to assist companies and public entities in the following activities:

Customized Funding Search and Partner Search We help organizations and their users (businesses, individuals, and the third sector) identify calls for proposals and funding opportunities (local, regional, national, and European) in a simple and targeted manner. We also provide support in the creation of international partnerships.

Project Design, Management, and Monitoring We guide our clients step by step throughout the entire project design and project management process, including monitoring activities, Quality Assurance, and impact assessments. We also specialize in supporting public procurement procedures and calls for sub-granting actions.

Physical and Financial Reporting We have extensive experience in reporting at all levels – local, regional, national, and European – with numerous financial instruments, interacting daily with databases and various checklists.

Capacity Building and Training We offer support to organizations in strengthening their capacities, not only through formal training programs but also through short and flexible interventions that ensure the continuous development of staff.

Communication and Information for Citizens and Stakeholders We also provide our expertise in communication activities aimed at citizens and stakeholders, organizing seminars, workshops, help desk services, personalized newsletters, and more.

Rachele Michelacci, Prospecto Srl

New has arrived

June 2024

Dear Followers!

We are pleased to announce that at the beginning of June, our ErgoDesign Team has been joined by a new partner from sunny Italy - Prospecto Srl. We are very excited about the new cooperation and we count on a fresh breeze in our sails!

Anna Stasiuk-Piekarska, PUT

Changes

June 2024

Dear Followers,

We are sad to inform you that at the end of May our wonderful and very helpful Partner ValueDo is leaving our project. Remembering the time we worked together, we wish ValueDo Team good luck and we do not say goodbye but see you in the future.

Anna Stasiuk-Piekarska, PUT

We are proud partners 2

June 2024

We are proud of our partners 2 Óbuda University facilitates the market entry of student innovations.

The recent collaboration agreement between Óbuda University and a student-led team, FilaMass (https://www.filamass.com/), specializing in advancing 3D printing technologies, aims to facilitate the market entry of student innovations.

As winners of the 2021 Proof of Concept (PoC) idea competition, FilaMass represents a significant step forward for the university in supporting student entrepreneurship. The agreement underscores the university's commitment to fostering innovative ventures. FilaMass aims to pioneer comprehensive 3D printing solutions that print and diagnose printing processes. Their creative approach has attracted attention, including them in the Start it @K&H Incubation Program, offering vital resources and networking opportunities for their development.

source: https://uni-obuda.hu/2022/04/25/kozos-start-up-vallalkozas-a-filamass-sal/

Gyula Szabó (OU)

Our Project Meeting in Prešov

June 2024

On June 3 and 4, 2024, a meeting of the members of the project team ERASMUS+ 2021-1-PL01-KA220-HED-000031182 "ErgoDesign – Improving digital skills for Ergonomics and Bioengineering Innovations for inclusive Health Care" took place in Prešov on the grounds of FVT TUKE, which under the leadership of the leader from Poznań University of Technology (Poland) enters the final phase of the solution (01.12.2021 – 01.12.2024). Other members of the consortium are: National Technical University of Athens (Greece), Technical University of Varna (Bulgaria), Oudai Egyetem (Hungary), Valuedo srl (Italy) and Technical University of Košice (Slovakia).

The project aims to create a new educational course for students to increase their knowledge of ergonomics and bioengineering, as well as their digital skills in the design and manufacturing of related products (dental and orthopaedic implants, prostheses and exoskeletons). The training course will take into account the specific requirements of people with special needs (health handicap) so that students learn to pay special attention to these target groups.

During the meeting realised in a hybrid form, the team members in a pleasant working atmosphere evaluated the activities carried out so far within the project and worked together on the preparation handbook that will enable replication of the ErgoDesign Course, on turning the Handbook contents into an e-learning course and on promoting the Handbook through webinars and a dissemination conference. In the afternoon and evening, the work meeting turned into moments spent together getting to know the centre of Prešov and a friendly discussion during dinner.

The organisers of the meeting would like to thank the Erasmus+ National Agency PL01 - Foundation for the Development of the Education System for the project funding. At the same time they would like to thank the management of FMT TUKE with a seat in Prešov for support during the project solution as well as for support at the organisation of this international meeting of the consortium members.

Katarina Monkova (TUKE)

We are proud partners

May 2024

EBK Hungary Engineering Trade Innovation Ltd. and Óbuda University have agreed to establish a relocated industrial department.

A close relationship has developed between EBK and Óbuda University in recent years. As a result of mutually beneficial professional processes, the decision to establish the new industrial department was made. In engineering talent supply, the company's human resources policy relies on students studying at the university while integrating the technologies employed by EBK into the curriculum. The collaboration holds significant opportunities for both parties, and the students graduate with competencies they can utilize from their first day of work.

EBK is a dynamic player in the engineering field, engaging in a wide range of activities, including research and development, manufacturing, and education. The company leverages the industry's most advanced software and industrial 3D scanners. EBK has a strong track record in both external and in-house research and development projects. A key highlight of their work is the application of cutting-edge 3D industrial and prototype printing technologies.

For Óbuda University, one of the most crucial aspects is collaboration in education, through which the company can provide topics, consultants, and development opportunities for students participating in the program.

Source: https://lnkd.in/dm29DSQY

Gyula Szabó (OU)

A short story of biomaterials

April 2024

The materials which have been employed throughout human history have defined its progress. The designation of civilizational ages—the stone age, bronze age, iron age, cement age, steel age, silicon era and nowadays, the age of new materials—effectively highlights the significance of materials. Considering our society both today and in the future, new materials are needed in every technical discipline, and the biomedical field does not differ.

Although biomaterials have been around for a very long time, the name and notion of biomaterials are relatively recent. A biomaterial is any substance that can be injected into a living organism or body without causing a detrimental biological reaction. The historical use of biomaterials dates back to ancient times; for instance, ancient Egyptians utilized animal sinew for sutures to stitch wounds.

Chrysi Giakoumidi (NTUA)

Ready to go!

April 2024

The ErgoDesign course is ready for boarding.

We are thrilled to announce that the testing phase of the online course on 3D printing of implants has commenced as part of the ErgoDesign Project.

The course is now open and available, although we primarily recruit participants from universities involved in the project implementation.

- First, create an account on the platform here: http://ergodesigner.tu-varna.bg/login/signup.php?

- Second, confirm your registration from your mailbox.

- Third, self-enroll in the ErgoDesign course here: http://ergodesigner.tu-varna.bg/enrol/index.php?id=3

Don't miss this opportunity to enhance your knowledge of implant 3D printing and contribute to advancing ergonomics and bioengineering!

Gyula Szabó (OU)

3D printers in medicine (2)

March 2024

Anna Stasiuk-Piekarska (PUT)

3D printers in medicine

Febuary 2024

(https://epoznan.pl/news-news-147543-skomplikowany_zabieg_w_poznanskim_szpitalu_z_pomoca_drukarki_3d)

Anna Stasiuk-Piekarska (PUT)

Conference announcement

January 2024

We are pleased to announce the next edition of the conference. More information you can find here:

„Dear colleagues,

let me invite YOU to submit YOUR article and publish YOUR research results in the journals listed below. Editorial board, article types and deadlines can be found using the links provided.

- Materials, CC WoS, IF 3,4 „Preparation and Application of Regularly Structured Porous Materials“

- Discover Mechanical Engineering, ISSN 2731-6564, "Recent Advances in Additive Technologies"

- III. Frontiers in Manufacturing Technology, ISSN 2813-0359, "Quality, Properties, and Manufacturing Conditions of Parts made by Additive Technology"

I look forward to hearing from YOU!

Kind regards,

Katarina Monkova (TUKE)

Merry Christmas!

December 2023

On behalf of ErgoDesign team, we would like to wish you merry Christmas and prospectus New Year 2024! The coming year is really important for us, so please do not forget to check our incoming news:)

ErgoDesign Team

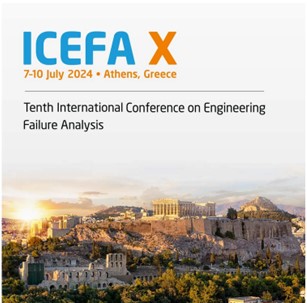

ICEFA X Conference

November 2023

Dear Colleagues, dear Friends!

Let me cordially invite YOU to attend the upcoming conference - The 10th International Conference on Engineering Failure Analysis, which will take place in Athens (Greece) during the term 7-10 July 2024

https://ww.elsevier.com/events/conferences/international-conference-on-engineering-failure-analysis

Abstract submission deadline: 26 January 2024

Katarina Monkova (TUKE)

Our new paper

October 2023

Have you already read our new paper entitled: “File Formats and Digital Data Transfer for Dental Needs” (Diana Pavlova, Tihomir Dovramadjiev, Dimo Daskalov, Rozalina Dimova, and Beata Mrugalska) published in Lectures Notes in Networks and Systems?

Abstract: The use of CAD/CAM in dentistry makes it possible to optimize the treatment process in case of a violation of parts of the orofacial complex. It contributes to the rationalization of the production process of the dental prosthetic structure by transferring file formats between different software programs for design, design visualization, simulation, and post-production through an additive or subtractive process. This electronic process has the ability to store larger amounts of medical data with different formats and transfer them between different software.

More info: https://link.springer.com/chapter/10.1007/978-981-99-3236-8_38

Beata Mrugalska (PUT)

Our Project Meeting in Varna

August 2023

Introduction

PR4 – short recap on the activities: what has been done and which are the next activities

After a short presentation by Tihomir of TUV team, Gyula of OU team provided a recap of the activities carried out so far and shared a number of suggestions with the consortium to make the course interactive. Gyula also reminded partners of the structure that each topic of the course should adopt.

1st day

PR4/A2: presentation and discussion for improvements of the topics from all involved partners

After a short break, the meeting moved on with a discussion of the topics prepared by the partners. This space was reserved for a group brainstorming on the work done by each topic’s author and to arrive at suggestions for improvement.

2nd day

PR3: presentation of what the course will look like within the Collaborative Platform; discussion for possible improvements.

Tihomir of TUV team presented the structure of the collaborative platform, focusing on how videos, presentations and quizzes will be displayed.

Partners agreed to have a single course composed of 14 topics. The full title of the course will be “3D PRINTING FOR INCLUSIVE HEALTH CARE (improving digital skills for ergonomics and bioengineering)”. All partners will be allowed to edit the course and upload autonomously the content that refers to the topics assigned to them.

Stefano Pianigiani (Valuedo)

Our Project Meeting in Budapest

May 2023

Introduction

The recent project meeting of ErgoDesign in Budapest marked a significant step towards the development of our innovative curriculum for ergonomic design and the promotion of e-learning in the field. Held on 16-17 May 2023, the meeting brought together project partners to discuss progress, curriculum design principles, platform improvements, and the implementation of training materials. This article provides a comprehensive overview of the meeting agenda and key discussions that took place during the event.

Day 1 - 16th May 2023

The first day of the meeting commenced with a warm welcome and the presentation of the agenda by Obuda University, setting the stage for productive discussions among the project partners. The participants delved into a comprehensive recap of the activities carried out in PR2, highlighting the achievements and outlining the remaining tasks required to successfully complete PR2.

The discussions then shifted to PR2/A3, which focused on a review of the Course Design Principles and their practical application in creating the ErgoDesign Curriculum. The partners engaged in a fruitful discussion, exploring how these principles could guide the development of module titles, content lists, learning outcomes, teaching methods, scope/duration of online training, and the recommended number of ECTS credits.

Following a brief coffee break, the project team reconvened for PR2/A4, where a detailed proposal for the ErgoDesign Curriculum and its components was presented. This encompassed a comprehensive overview of module titles, content lists, learning outcomes, teaching methods, recommended scope/duration of online training, and the suggested number of ECTS credits. The partners actively participated in a validation process, ensuring that the proposed curriculum aligned with the project's objectives and adhered to the Course Design Principles.

The discussions continued with PR2/A4, which focused on finalizing the validation of the ErgoDesign Curriculum and its components. The partners provided valuable feedback, enabling necessary revisions and reaching a consensus on the curriculum's structure and content.

Additionally, the partners discussed the Interim Report. PUT and ValueDo clarified its timeline, the required contributions from each partner, and the expected outcomes.

Later in the day, updates on dissemination activities and the overall work plan were presented by PUT. The partners shared their accomplishments in disseminating project outcomes and engaged in constructive discussions to maximize the project's visibility and impact.

Day 2 - 17th May 2023

The second day the focus shifted to PR3, with a presentation on the project platform by Technical University of Varna and proposals for its improvement. The partners actively engaged in discussions on enhancements and modifications to ensure an optimal learning experience for the ErgoDesign e-learning platform.

Then, attention turned to PR4, centeringaround the "ErgoDesign e-learning Training Materials." The partners received an overview of PR4 activities by Obuda University team, including a presentation of the key elements of the course preparation Action Plan and assessment materials. Collaborative brainstorming and idea sharing took place regarding the practical implementation of the pilot course.

The meeting concluded with a recap of tasks and deadlines, ensuring that all partners were aligned on the next steps and responsibilities. Final conclusions were drawn, acknowledging the progress made during the meeting, and expressing appreciation for the active participation and collaboration of all partners.

In conclusion, the project meeting held in Budapest was instrumental in advancing the ErgoDesign project's objectives. The discussions and decisions made during the meeting propelled curriculum development, platform improvements, and the preparation of training materials. The partners' dedication and collaborative efforts have brought the project closer to its goal of promoting ergonomic design through innovative e-learning methodologies.

Giuditta Pasta (ValueDo)

The necessity of 3D CAD software

in biomedical technology

April 2023

The medical device manufacturing industry is growing rapidly in order to keep up with the increased demand. Therefore, medical device product designers must create innovative medical products. Plenty of challenges are to be considered during the manufacturing of medical equipment, with the most important among them being patient safety. Efficiency, effectiveness, and cost containment, are also very important to be considered.

Therefore, the use of 3D CAD software in biomedical technology is necessary.3D CAD is a three-dimensional computer-aided design tool used by designers, engineers, and architects to create industrial objects that include complex mechanisms.It helps to create functional, virtual prototypes of three-dimensional designs.CAD software can be very specific, whether it is for industrial, mechanical, architectural, or aeronautical engineering design.

CAD software tools allow designers to investigate design ideas, modify designs easily, visualize concepts through renderings, simulate how a design performs in the real world, and draft documentation. Moreover, using cad software designers can share designs for feedback, and allow companies to get to market faster. In the biomedical field, CAD software is used for accurate modeling of complex geometries, customization, and patient-specific solutions, iterative design processes, simulation and analysis, collaboration, and communication, as well as facilitating manufacturing and production. More specifically CAD is necessary for the following reasons:

- Precise Design: Biomedical technology often involves intricate and complex designs, such as medical devices, implants, and prosthetics. CAD software allows engineers and designers to create precise and detailed 3D models of these components. It enables accurate representation of complex geometries, dimensions, and specifications, ensuring the design meets the required standards and functional requirements.

- Visualization and Simulation: CAD software provides visualization tools that allow designers to see the virtual representation of their designs in 3D. This visual feedback helps in assessing the aesthetics, ergonomics, and functionality of biomedical devices. Additionally, CAD software often includes simulation capabilities, allowing engineers to test the performance and behavior of the devices under different conditions. This simulation helps identify potential design issues and optimize the performance before physical prototyping.

- Customization and Personalization: Biomedical technology often requires customized and patient-specific solutions. CAD software enables the creation of personalized designs based on patient data, such as medical imaging scans. With CAD, engineers can precisely model and modify the design to fit the unique anatomy and needs of individual patients. This customization enhances the effectiveness and comfort of biomedical devices, leading to improved patient outcomes.

- Iterative Design Process: CAD software supports an iterative design process, where designers can make changes and refinements to their designs based on feedback and testing. The software allows for easy modification of design parameters, enabling rapid prototyping and evaluation of design iterations. This iterative approach leads to the development of optimized and efficient biomedical devices.

- Collaboration and Documentation: CAD software facilitates collaboration among multidisciplinary teams involved in biomedical technology development. It allows for the sharing and exchange of design files, enabling effective communication and feedback from clinicians, researchers, and manufacturers. Additionally, CAD software enables the creation of comprehensive design documentation, including detailed specifications, measurements, and material information. This documentation is essential for regulatory compliance, manufacturing, and quality control.

- Integration with Manufacturing Technologies: CAD software plays a crucial role in the integration of design with manufacturing technologies in biomedical engineering. The CAD models generated using the software can be directly used in various manufacturing processes, including additive manufacturing (3D printing), CNC machining, and mold fabrication. This integration ensures accuracy and consistency between the designed model and the manufactured product.

Overall, CAD is necessary in biomedical technology for precise design, visualization and simulation, customization and personalization, iterative design processes, collaboration and documentation, and integration with manufacturing technologies. It enhances the efficiency, accuracy, and innovation in the development of biomedical devices, leading to improved healthcare outcomes.

Chrysi Giakoumidi (NTUA)

Popularization of surgery

with the use of 3D implants

March 2023

In recent days, information has appeared in the Polish media about an operation performed in Poznań with the use of an endoprosthesis produced with the use of 3D printing.

The operated person, suffering from many different diseases, has not been able to take a step for the last year. It was caused by a defect in the pelvic bone, as a result of moving around for many years with too loose an endoprosthesis. Now, after implanting an implant that takes into account the anatomy of that person, the patient can walk again (https://gloswielkopolski.pl/lekarze-z-poznania-wszczepili-endoproteze-wydrukowana-w-3d-implant-szyty-na-miare-to-przelom/ar/c14-17418373).

The use of implants can be also a therapy for people after oncological treatment, when the cancer attacks the bones and they need to be removed. In large cavities, a typical implant cannot be used - it must be made specifically for a specific patient. Precise specification is necessary before the procedure, using, among others, computed tomography and magnetic resonance imaging. Only then the implantsare printed (https://www.prawo.pl/zdrowie/poznan-najwieksza-w-polsce-udana-operacja-ortopedyczna-z-uzyciem-druku-3d,244844.html).

At present, in Poland, endoprostheses made in 3D technology are implanted only in a small group of patients. The problem is particularly important because each of us is different and tailor-made prostheses are the future!For comparison, specialists from the City Hospital. J. Strusia in Poznań install approx. 500 mass-produced hip and knee endoprostheses annually. 3D printing gives a chance to treat those patients who were previously unqualified for it. In recent years, only 3 such procedures have been performed in Poland (https://www.poznan.pl/mim/info/news/wyjatkowa-operacja-w-miejskim-szpitalu,200562.html).

The ErgoDesign project aims to support the development of specialists in this field, to make this therapy more accessible by educating more specialists in the field of bioengineering and biomechanics. Not only in Poland, but all over Europe!

Additive technologies

are on the rise in today's world

Febuary 2023

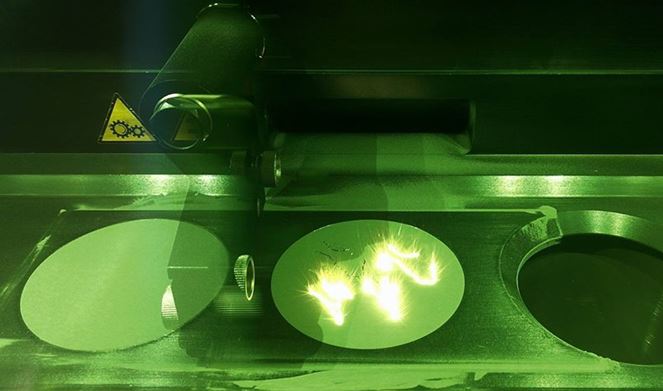

Additive technologies are on the rise in today's world. 3D printing has appeared in almost all areas of industry and life, allowing the rapid creation of unique pieces. Additive technology is also playing a role in medical technology, with dental technology being the fastest growing. In the production of dental implants, each piece is unique, because each tooth is individual, like a fingerprint. Several methods can be used to produce the implant, which is the result of careful condition assessment, design and manufacture.

7th International Conference of Engineering Against Failure

January 2023

Dear Colleagues, dear Friends!

More information about the conference can be found in the new official website of ICEAF VII: http://iceaf.eu

Registration process is open and YOU are kindly invited to register HERE by filling in the Conference Registration Form.

Full length conference proceedings following to peer review will be published in dedicated peer-reviewed and open-access issue of the publication series Journal of Physics: Conference Series (JPCS) (Online ISSN: 1742-6596 with 2021 Cite Score 0.8 and Scopus Indexed) of the IOP Publishing Ltd.

Furthermore, selected papers from the ICEAF VII Conference will be published in special volumes of the international highly reputable scientific journals: Engineering Failure Analysis, International Journal of Fatigue, Theoretical and Applied Fracture Mechanics, following to peer review.

Should YOU have any additional queries, please contact the Conference Secretariat at info@iceaf.eu.

Looking forward to hearing from YOU and meeting YOU in Spetses.

The ErgoDesign team

wishes You

a Merry Christmas

and

a Happy New Year 2023!

ErgoDesign Meeting,

November 2022

ErgoDesign - Erasmus+ Project during the Science Month at Varna University of Technology, October 2022

The Science Month 2022 at Varna University of Technology began with the opening of the exhibition/competition "SCIENTIFIC ACHIEVEMENTS OF THE UNIVERSITY OF TU - VARNA" on October 10, 2022.

The event was officially opened by prof. Eng. Todor Ganczew, vice-rector for scientific activity. The event brought together students and lecturers of Varna University of Technology.

Our Project implemented as part of the Erasmus+ project was also among the presented scientific activities!

1st Transnational Project Meeting, September 2022

ErgoDesign Meeting,

August 2022

In August 2022, the partners agreed on the final agenda for the meeting in Athens. The meeting will be hosted by NTUA and will last two days. NTUA, as leader of PR1, will have the occasion to present the results of the evaluation from external expert on Dynamic Toolkit, to discuss possible improvements for the final version of the DT. PUT and TUV, respectively leaders of PR2 and PR3, will present the progress of the activities, asking for partners’ contribution and feedback.The ErgoDesign partners are looking forward to finally working together in person, after almost one year from the beginning of the project… Athens will be the perfect spot for this first meeting!

Giuditta Pasta (Valuedo)

ErgoDesign Meeting,

July 2022

The Dynamic Toolkit aims to help its users, usually professionals from the medical sector, to put in order the various digital tools that can be used for designing and producing 3D printed models of any kind of medical implants, to systemize them according to a common format and to create a tool that can help them select the suitable software for the right purpose.

ErgoDesign Meeting,

June 2022

In June the project consortium received their passwords to test in real the intellectual project output PR3 – ErgoDesign collaboration platform. The platform will have a lot of engaging content to offer but we started from creating our own profiles.

Tihomir Dovramadjiev (TUV)

4th Virtual Meeting,

May 2022

The leader of the PR1, NTUA represented by Angelos Markopoulos, presented the software described by all the partners. The descriptions of the tools will represent the basis for the construction of the Dynamic Toolkit that will be made available in beta version for internal and external tests.

The leader of PR2, Beata Mrugalska (PUT), updated the partners on the state-of-art for PR2. All partners will collect information on how HEI courses in topics related to ergonomic and bioengineering are designed and delivered in EU countries, focusing on methods and topics. Special attention will be given to aspects relating to people with special needs’ requirements, so to provide information all along the modules design, of which the curriculum will be composed of, and develop a specific module in the final curriculum. Partners will also analyse good practices in other countries referring to training methodologies and practical activities meant for training students in the use of software and digital tools.

The leader of the PR3, TUV represented by Tihomir Dovramadjiev, presented the collaborative platform which is integrated in the Moodle. In the next step it will be integrated within the ErgoDesign project website.

Anna Stasiuk-Piekarska (PUT)

3rd Virtual Meeting,

April 2022

The leader of the PR3, TUV represented by Tihomir Dovramadjiev, presented the collaborative platform which we will be an easy-to-use interface, designed to be responsive, accessible, easy to navigate on desktops and mobile devices, conceived to allow a two-way sharing between trainers and learners: learners will get training and information, but also will provide them. It will be of paramount importance for ensuring the sustainability of project outcomes (dynamic toolkit, curriculum, training materials, exercises, Trainers’ Handbook, e-learning course, all other training materials available in this one-stop shop) and their exploitation (freely available for 5 years after the project’s end). All the partners discussed the technology they would like to use to the collaborative platform.

Anna Stasiuk-Piekarska (PUT)

2nd Virtual Meeting,

April 2022

The leader of the PR1, NTUA represented by Angelos Markopoulos, asked all the partners to choose and describe the software we already know and use in practice, even if it will be possible to add more software besides the proposed ones we choose to work on. For this aim, we defined the template how the description of the software should look like to collect the similar results.

Anna Stasiuk-Piekarska (PUT)

1st Virtual Meeting,

March 2022

The leader of the PR1, NTUA represented by Angelos Markopoulos, explained the further steps for this project result. In the incoming weeks all University partners will identify software/digital tools according to the technical specifications defined in PR1/A1 and fill in the template for the description of the software/tools.

Anna Stasiuk-Piekarska (PUT)

Kick-off Meeting,

January 2022

On 24-25.01.2022 the first meeting of the consortium implementing the Erasmus + ErgoDesign project took place. The partners presented their achievements and plans for the implementation of the project. The area of project management and reporting, administrative and financial issues and Quality Assurance Plan were presented.

On the second day, presentation, and discussion of the proposed action plan (methodology, upcoming tasks, responsibilities) and technical requirements and functionalities of the online collaborative platform were presented.

The aim of this block was to: ensure that all partner agreements are signed, appoint Steering Committee members, discuss channels of communication, agree on the schedule of virtual meetings, validate the dates and places of project meetings, present project indicators etc.

Beata Mrugalska (PUT)

Positive verification,

December 2021

Yupi! We are happy that the ErgoDesign project has been positively verified in the Erasmus + program. We are starting work on the project which supports the introduction of ergonomic and bioengineering innovations in implantology and prosthetics. The leader of the Consortium is the Poznan University of Technology.

Beata Mrugalska (PUT)